It’s been both an eventful two months since our last post, while also being a frustratingly slow two months… with excavation finally starting on the house and garage; turns out the excavation was the easy part, as getting the footer and basement walls formed and poured took the best of about a month.

During the downtime, we stayed quite busy with some new farm forestry equipment, including a side-by-side utility vehicle and a tractor. We also cleared and developed trails, pruned and thinned tree stands near the house and garage, met with two forestry professionals, planned and installed a raised-bed garden, completed a survey of our property, dismantled two decrepit sheds, split firewood, planned and built a woodshed, and began the long process of removing the horribly invasive knapweed that is too prevalent on our property.

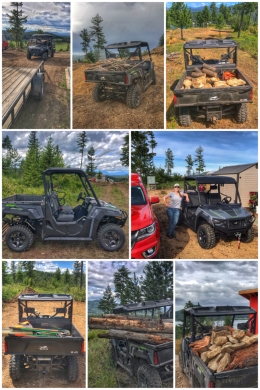

The first piece of equipment we purchased for H3 (Hansen Hilltop Haven) was an Arctic Cat Prowler Pro, which we purchased from Protection Plus, in Deer Park. We had been carting stuff by hand or via a wagon — and on 30 acres, that becomes a bit too much… so we went shopping for a side-by-side utility vehicle. Our goal was to find a workhorse that seated at least two people and which had a dumping back bed. We did a lot of searching online… and found quite a few models available (many of which shipped via freight in pieces), but none quite right. So we decided to test drive a few models at Protection Plus, including a Kymco and can-am, but completely fell in love with the Arctic Cat — because of its front bench seat (which seats three comfortably), power, and very quiet motor (compared to the other two models). We named our utility vehicle Artie — and he has been a workhorse ever since, carrying loads of slash, knapweed, rocks, dirt, and more!

We also knew we needed a tractor, but that search was even more difficult, partly because of the various brands and partly because we wanted to find the best dealership for servicing it when needed.

After comparing a multitude of brands — from John Deere to Branson to Kubota to Mahindra to New Holland — we decided on a Kioti… more specifically, a Kioti 3510 HST, a 35-horsepower, hydrostatic-controlled, tractor with a loader and bucket and PTO. We also purchased two accessories with it: a bush hog (for mowing trails and creating new trails) and a snowplow (for clearing the driveway in the winter). We had considered also purchasing a PTO-driven chipper, but the total cost put Ran into a bit of a spell, so we are saving the chipper for a future purchase.

We again shopped and purchased locally — this time at Hartill’s Mountain Saw & Tractor. We fell in love with the tractor because of its higher horsepower than similar “compact” tractors — and we chose Hartill’s because of its location and reputation.

The tractor has already been put to great use, helping level and form the garden, lift and remove massive root balls and other tree debris (that we will burn in the winter), push dirt around the property, clear trails (and make new ones), and fix spots in the driveway damaged from heavy machinery.

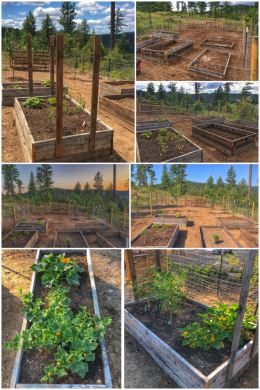

Speaking of the garden, we knew when we bought this property that we wanted a garden so that we could enjoy fresh fruits and vegetables — and also gain more control over the foods we eat — and we expected not to have the time to deal with planning, fencing, and planting a garden… but with delays in the house construction, we found time on our hands — and we also found a new friend who was selling old boards… which we decided to repurpose into five raised beds (only two of which we are using this year).

Ran plotted out the dimensions of the garden, used the tractor to prepare the area (which included a massive pile of dirt from when the water reservoirs were installed), and then set about digging all the post holes for the double-fencing system we are using to protect the garden from deer. (The fence is only 4-feet high, but uses a second 4-foot high fence about 3 feet apart, which confounds deer, at least according to several experts.)

We filled the raised beds with some of our “best” dirt (bits of topsoil scraped off the top when the reservoirs were being installed), but amended the beds with a layer of organic soil designed specifically for raised beds, as well as aged manure from a good friend from whom we buy fresh chicken eggs.

For the raised beds, we bought some tomato, squash, cucumber, and pumpkin starts at a few of the local farmers markets — all from non-GMO, heritage seeds. We also planted some raspberry starts our builder Jason gave us, as well as several lilac plants we purchased for Ran’s birthday. We later splurged on some elderberry and chokecherry bushes, as well as one Honeycrisp apple tree and one Lambert cherry tree.

We are happy to report that the garden is doing well — so far. We have enjoyed several tomatoes (with lots more ripening), several zucchini, and about to have our first cucumbers. We cannot wait until next year when we can add kale, string beans, and spinach to the mix!

While we struggled to find and meet with other excavators, we were able to check off another important issue we wanted to address: a complete survey of the property, including finding and marking all corners, as well as marking along the property lines.

We also had a bit of a struggle finding a surveyor who was willing to do a little extra legwork in finding all the documentation, but we are extremely happy that we contracted with Todd Emerson of Emerson Surveying.

As you can see from the pictures, we had to do some serious bushwhacking through the brush and fallen trees on the property. Ran and Todd soldiered through on two different days, finding all the recorded pins/corners and actually installing one new pin. During the process, we discovered a neighbor had created trails on our land and we quickly corrected them about the property lines. We look forward to the final recorded survey in a few weeks — and doing more work on marking lines in the fall when the weather is a bit cooler.

After several delays and some very extravagant bids for excavating, we found a young company eager to establish a relationship with our framer — and someone who could do the job in a timely fashion, as well as within budget. (We had received some seriously exorbitant bids, partly because of the pandemic — or should we say from the government’s reaction to the pandemic in shutting down businesses as “non-essential.”)

Within just a few days of work, we had the house daylight basement excavated, a new roadway between the house and the garage created, the garage slab area excavated, and improvements to the driveway (including the installation of a culvert to help move rain off the driveway). There were several issues and problems encountered along the way — including the orientation of the house and some pesky massive basalt and granite stumbling blocks that caused the house to be moved a few feet from its original planned location.

Most importantly, after months of waiting, we finally had made some progress toward constructing the house. Of course, once we had found an excavator, we jumped into searching for a concrete company, soon discovering that concrete footings and walls contractors are different than concrete floor (flatwork) contractors.

The company we hired for the job was good from the standpoint that its work was solid, but the main contractor was a bit full of himself and we think our job was simply a quick add-on to other projects he was working on — which meant multiple delays in getting the footings poured and delays in getting the walls poured. Of course, because of the pandemic and building backlogs, it also took several days to get the inspections completed for each element, adding to the delays.

The one cool thing — but also over the top for such a small project — is that the contractor used a concrete pump truck to deliver the concrete into the forms — and as you can see from the pictures, it was very cool to see… and certainly a very fast and efficient method for pouring the concrete.

While we were on a constant start and stop mode with the house, we decided to tackle our own building project — a woodshed to protect all the firewood for the woodstove we plan to have in the basement of the house.

Ran designed the shed, bought all the materials, and with Jen’s help, constructed the shed — all within a period of about two weeks… so we win the award for best and most efficient contractors!

Ran utilized the floors of two odd shacks we discovered on the property, along with two shipping pallets — to construct an 8′ x 16′ woodshed. All the materials came from a local lumber store in Loon Lake, Baldwin Building & Lumber Supplies.

The building is in essence, a small pole barn, using 4 x 4 poles and 2 x 6 girts. The roof uses 2 x 6 trusses, with OSB panels. The siding is T1-11 siding. Ran built the barn door from leftover materials (2 x 6 frame, T1-11 inserts, and 2 x 4 horizontal supports). We debated about the colors for the woodshed, but with the help of Ran’s brother Wes, we decided to reverse the colors we plan to use on the house and garage — grey siding with orange-red doors — to make the woodshed make a bit of a statement as it sits on a hill just above the house.

When we were not working on the woodshed or doing our daily “real” work, we also decided to dive headfirst and make a major dent on the knapweed problem that has been allowed to fester on the property for decades.

Knapweed is not only an invasive species, but a noxious one at that! It spreads by both sending out roots for new shoots and by seed. It also secretes a poison that kills off competing plants so that it is easier for it to spread. The best way to remove the plant is by hand-pulling EACH plant, which often requires using a shovel or spade to dig down to remove all the roots. Some people treat knapweed with herbicides, but we are trying to protect our soil (and wildlife) and will not use any harsh chemicals. In a few areas of our land, we hope to engage a bioagent (bugs) that eat knapweed.

Knapweed is usually found along driveways and roadways — and further spreads through vehicles unknowingly carrying the seeds. Hay from fields with knapweed also spread the weed. Logging is also another big spreader of knapweed — and our knapweed can definitely be traced to when the property was logged in the 1990s.

Just in case you were interested, knapweed is related to the thistle, also a nasty and invasive weed. It is native to Europe and Asia, brought over to the U.S. on shipping containers. The worst offenders in this area are spotted knapweed, meadow knapweed (a hybrid), diffuse knapweed, and Russian knapweed.

Back to the construction, after much delays, we finally completed the last phase of the concrete work, with our plumber Don from Plumbtech arriving (on one of the hottest days of the summer) to install the basement rough-in plumbing. Once that work was completed, we could backfill the inside basement walls with pea gravel, install rebar, and pour the floor. We hit one snag when we had our first failed inspection as the building inspector wanted a complete plastic sheeting under the rebar to keep any potential radon gasses from seeping up into the concrete floor. Once it passed inspection, we had a great crew from Palm Beach Construction Company do the installation and finish work on the basement floor… which means, we now enter the next phase of construction: framing!!!

One final note… During all these weeks, we did not just sit around on the property or work all the time. We did make a few trips off the property to explore the area, find some new hiking adventures, and support local suppliers of fresh fruits… more on those experiences in the next post!